廣州市銀標(biāo)貿(mào)易有限公司

聯(lián)系人:賴先生

手機:13922125860

固話:+86-20-23830796 23830403

傳真:+86-20-34637699

網(wǎng)址:m.rjrer.com

郵箱:laiqiangping2010@163.com

地址:廣州市番禺區(qū)鐘村鎮(zhèn)鐘榮路1號致業(yè)科技中心A棟3樓AS388#

gzyinbao has combined Printed Electronics and textile printing to offer new conductive and protective inks for printing stretchable electronics on fabricInks

gzyinbao provides an assorted range of materials for “Stretchable Electronics” applications, such as:

Silver Based (micrometric flakes) Conductive Inks

Protective/Encapsulating Inks

Adhesive inks for Transfer Printing

All the Inks are:

Water-based

Screen printable

Highly stretchable (tested up to 100% of elongation)

Protective/ encapsulating inks are used in synergy with conductive inks. Their functions are:

Structural support/mechanical stress absorption

Barrier to water (for washing resistance)

Electrical insulation

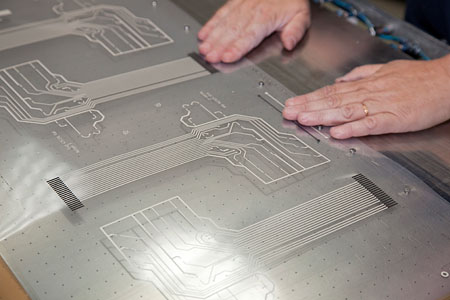

Printing Technology

elastic (TPU) membranes are used as printing substrate to be further laminated on the final product surface:

In case of textile applications (smart-garments, wearable technology type of applications) the transfer printing technology is used to transfer, by heat and pressure, the ink layer set from a sacrificial substrate to the final fabric

In case of other applications the printed stack of inks can be peeled-off from the sacrificial substrate for further handling

The transfer printing process is explained in the picture below.

Figure 1. – Process in the case of final application on fabric

Ink layers and a thermoplastic glue are screen printed on a sacrificial substrate

The ink layer set is transferred, using a heat press, by activating the thermoplastic glue (current parameters are: 180°C/4 bar/15 sec)

The sacrificial substrate is peeled-off

Final curing is performed (5 min at 150°C for best performances)

The adopted technology has a few advantages:

Reliable printing on a smooth and stable (sacrificial) substrate

Full additive and simpler process. No membrane laser cutting-out is required as the printing substrate is totally removed after the transfer of the ink stack onto the final substrate

Better “l(fā)ook and feel” and comfort. No permanent intermediate substrate is left on the fabric.

Electrical performances under strain

There is no standard to evaluate stretchable conductive Inks. We test our inks with single elongations, up to 100%, and repeated cycles (typically 1000) of 0-20% elongations.

Initial sheet resistivity is <30 mOhm/square@25micron (after curing of the ink at 150°C for 5min). The below graphs show the typical resistance behavior under strain.

Figure 2. – Single stretch

The above performances relate to a straight line conductive trace 150mm long/4mm wide

According to our experience many factors affect performances under strain:

Ink silver flakes characteristics, concentration and mix

Protective inks. Protective inks more resistant to washing exhibit a lower elasticity. This affects the overall electrical performance, especially under repeated strains

Final fabric, in particular the weave more than the raw material

Trace shape. Straight lines and corners are not the best performer

gzyinbao has developed base conductive inks and a few protective inks which can be customized for the specific application.

Please contact us ( laiqiangping2015@gmail.com) to evaluate ink performances against your requirements

The offering

Stretchable electronics, offerta

gzyinbao can provide either the inks or the printed layer set ready to be transferred to the final fabric. The second option is recommended for initial tests or quick feasibility studies.

gzyinbao can provide direct assistance to Clients in the fine tuning of the printing processes, in the assessment of performances and in the evaluation of possible ink customizations.

E-mail: laiqiangping2010@163.com laiqiangping2015@gmail.com